3 Most Important Elements of Forklift Safety

Forklift safety is an important issue that needs to be addressed in every workplace that uses lifting devices. According to the Occupational Health and Safety Act (OHSA) statistics, about 85 forklift fatalities and 34,900 serious injuries occur each year, with 42% of those fatalities resulting from the driver being crushed by the vehicle tipping over. According to WSIB, workers have also suffered critical injuries such as broken limbs, cracked ribs and head injuries as a result of falling off a lift truck. Read on to discover the 3 most important elements of forklift safety, including proper training, proper equipment maintenance, and work environment awareness. If you require proper forklift safety training for your workers, contact Wayco today.

Proper training is key to forklift safety

1. Proper and Comprehensive Forklift Safety Training

Proper training of all forklift operators is not only a good safety practice but is also required by law. OHSA mandates that all powered industrial truck operators be properly trained and certified by their organizations.

a) Types of Training Required

Every employer is required to design and put into place a training program that includes:

- Safe lift truck operation training

- Specialized training on the operation of the particular type of vehicle used in the workplace

- General safety requirements as outlined in the OHSA standard.

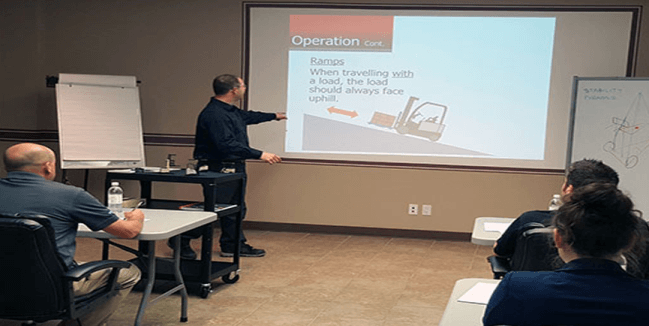

Proper training should take the form of both formal and practical training. Formal training could include in-classroom lectures and videos while the practical training would involve demonstration and hands-on practice.

The OHSA lists all of the training topics that must be covered in the training, however, you can skip those topics that are not relevant to your particular working situation.

Training should consist of both classroom and practical components

b) When Training Should Occur

Before a New Employee Begins Work:

Before an employee is allowed to operate a lift truck, an employer must evaluate and determine whether or not they are competent to operate a powered industrial truck safely. Even if the operator has previous experience using forklifts, they still need to be properly trained on the types of vehicles used at your worksite as each piece of equipment and each worksite is different.

At Least Once Every 3 Years:

Employers are responsible to make sure that their forklift operators are trained and evaluated at least once every three years.

c) Who Should Administer the Training

Training must be led by a qualified trainer. There are reputable forklift training companies who will either come to your premises to perform the training for your employees or, if you prefer, you can send your operators to their facilities to have the training done.

Make sure your forklift training is led by a qualified trainer

d) Best Safety Practices

The following are a list of best safety practices that you should learn and put into practice in order to operate a forklift safely.

- Always perform a pre-shift inspection before you begin operating your vehicle.

- Always make sure that your load is properly and safely arranged on the forks.

- When moving your lift truck keep your load lifted just above the pavement with your forks tilted back just enough to stabilize your load.

- Keep your speed slow enough that you can stop safely within your stability triangle.

- If you are travelling on an incline, keep your load facing uphill not downhill.

- Slow down when you are driving on slippery surfaces and when you are making turns.

- Try to drive on clear surfaces that are free from debris, ruts, or holes.

- Use your horn when you come to an intersection or whenever your visibility is blocked.

Pre-shift inspections should always be done before operating your lift truck

2. Properly Maintained Lift Equipment

Making sure that your lift equipment has been properly maintained and is in good working condition goes a long way toward ensuring forklift safety.

One of the initiatives that the Ontario government is taking as part of the province's Safe At Work Ontario compliance strategy is that inspectors will check that employers that use lift-trucks and other lifting devices will have them examined for their load capacity and verify that they have been maintained in good condition. These initiatives were put in place in order to raise awareness of workplace hazards and promote compliance with the Occupational Health and Safety Act (OHSA).

The following are some of the hazards that safety inspectors look for when they are conducting their forklift safety inspections:

- Are the tires in good condition?

- Is the seat in good condition?

- Is the mast in good condition?

- Are the forks cracked or bent?

- Has the forklift had its annual inspection to make sure that it is capable of lifting the rated load of capacity?

- Is there a working fire extinguisher readily available?

- Is there a working seatbelt?

The following video produced by the Ontario Ministry of Labour further outlines what is involved in one of their inspections.

3. Work Environment Awareness

The workplace environment itself can also affect your safety. The type of facility that you work in and the condition of your surroundings can present hazards for forklift operators.

Retail Settings: If you are working in a retail environment, you will find it more difficult to maintain pedestrian safety as customers may not pay attention to warning signs and inadvertently wander off their designated paths.

Debris: Loose objects left on a warehouse floor can cause you to lose control of your steering.

Wet, Oily, or Icy Surfaces: These types of surfaces should always be avoided and should be cleaned up as soon as they are detected.

Soft Dirt: If you are operating a lift truck outside, you should be aware that your wheels may sink on a soft dirt surface which could cause your elevated load to destabilize.

Loading Docks: Loading docks can be a hazard to lift operators. Many accidents occur when a truck is mistakenly driven off the edge of the dock or by the dock itself collapsing. The following video shows a forklift falling off a loading dock.

Contact Wayco for the Best Forklift Training Available

Wayco's intense and comprehensive forklift safety training program will provide you and your employees with the best safety training at the best price. We offer national coverage and local service with a 98% pass rate. We can train individuals or groups at our facility or yours - you choose.

Our Safe Operation of a Lift Truck/Forklift Program is an excellent way for you to ensure forklift safety in your workplace. With our training you will experience:

- Innovative training practices

- Affordable pricing

- Flexible and professional trainers

- Comprehensive in-class and practical experience

Contact Wayco today to book your next session.

"Exceptional quality and service. Left the training class with more than I expected. Looking forward to being a repeat customer. " - Kevin Brown

Read more testimonials here.

If you are looking for top quality forklifts, contact Wayco. We sell the best forklifts you can buy and our knowledgeable staff will be able to help you choose the perfect model that will best suit your particular applications. We will be happy to answer all of your questions and we can even provide top-notch safety training for your operators. Contact Wayco today for all of your forklift needs.