3 Things You Need to Know about Forklift Maintenance

Proper forklift maintenance will ensure that your lift truck will last longer, run more economically, be more efficient, and most importantly, be safer for your employees. Read on to find out the 3 things that you need to know about forklift maintenance. Looking for a reliable and trusted company to regularly maintain and repair your forklifts for you? Contact Wayco today.

It is important to check the tires for signs of wear

Forklift Maintenance

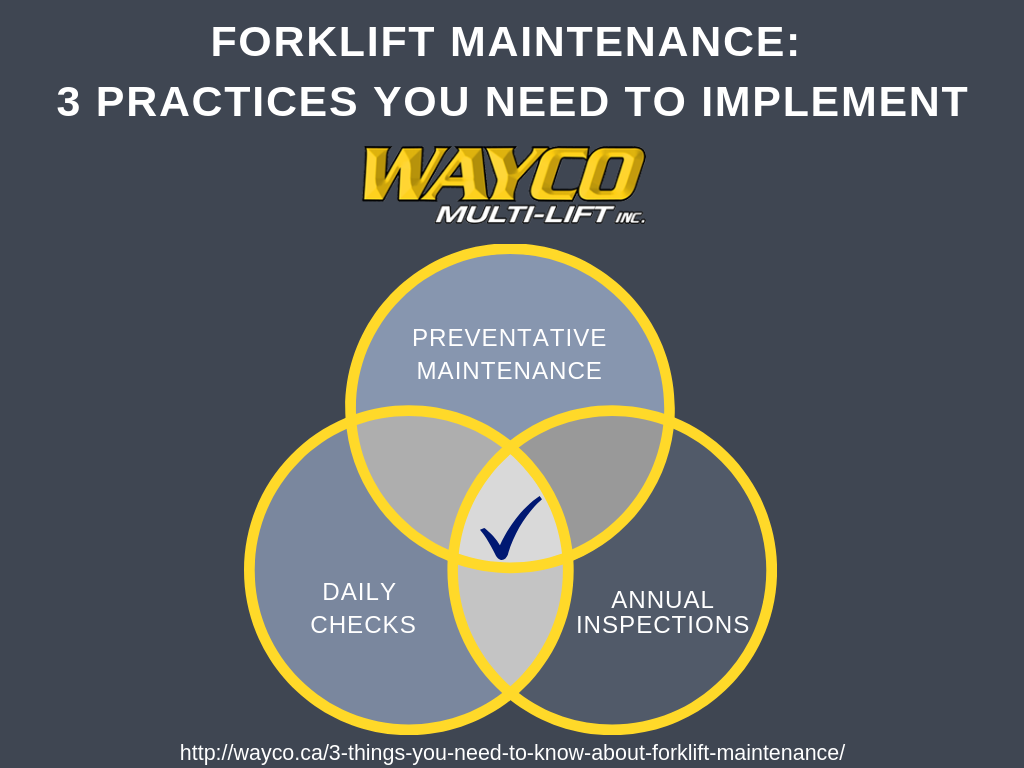

Regular forklift maintenance will not only help your machine to last longer, be more productive, and, as a result, save you money in larger repair costs and downtime, but it will also ensure that your operators and other workers are safe. Forklift incidents can cause serious injuries or even death, so it is very important that they are well maintained in order to better protect the safety of your employees and your business. The 3 areas of regular maintenance include:

- Daily Maintenance Checks

- Preventative Ongoing Maintenance

- Annual Inspections

1. Daily Maintenance Checks

At the beginning of each shift, a forklift operator is required by The Occupational Health and Safety Act, known as OHSA, to do a daily maintenance check on any vehicle that is operated daily. This is also known as a Pre-Shift Inspection.

Here is a sample checklist that you can follow prior to operating your lift truck. If you would like to order a pre-shift inspection checklist that you can use during your daily maintenance checks, click here.

.

During your daily maintenance check you need to take a close look at the following:

- Forks - look for weld breaks, raise and lower the forks with and without a load

- Tires - check to see if there are any chunks of rubber missing

- Piston - check to make sure there are no leaks or drips

- Hydraulic hoses - look for any punctures or cuts in the hoses

- Chain - make sure that the tension on the chain is tight

- Carriage - look for any weld breaks

- Seat belt - make sure it is in good repair

- Propane tank (if it has one) - make sure it isn't loose

- Radiator - make sure that there isn't any debris or trash caught in it

- Emergency brake and accelerator - make sure that they are functioning properly

- Controls - ensure that they are all in good repair

- Safety lights, battery, alarms, & horn - make sure they are all functioning properly

- Fluid levels - check your engine oil, fuel, radiator water, and hydraulic fluid levels

If you find that during your inspection any of the above items are unsafe or needing to be repaired, your forklift needs to be taken out of service, red tagged, and repaired before you use it again.

The following video will demonstrate how to effectively carry out a pre-shift inspection.

For more information on pre-shift inspections, check out our blog post entitled "Forklift Pre-Shift Inspection."

2. Preventative Ongoing Maintenance

Performing preventative maintenance is the best way to make sure that your lifting device is operating at its best. By being proactive and scheduling regular maintenance work according to the manufacturer's recommendations for your lift truck you will be making sure that your forklift will have lower repair costs, higher efficiency and productivity, and a longer life.

Regular maintenance will help prolong the life of your forklift

Maintenance to be Done Once a Month

Every month or 200 hours (whichever comes first), a trained mechanic should perform the following maintenance tasks on your lift truck:

- Inspect the lift and tilt cylinder operation

- Check the drive belt tension

- Lubricate the chassis and mast parts

- Replace the engine oil

- Clean the air filter

In addition, if your truck is engine powered

- Inspect the spark plugs and distributor point

- Check the cap and rotor

- Adjust the engine idle speed and ignition timing

Monthly maintenance should be done by a trained mechanic

Maintenance to be Done Once Every 3 Months

Every three months or 600 hours (whichever comes first) you should have the following maintenance done:

- Clean the exterior of the radiator and replace the fuel filter

- Replace the hydraulic filter

- Adjust the mast support bushing, tilt cylinder pins, and chassis links

For engine powered forklifts

- Inspect the pedal free play, hand brake, lift chain tension, mast operation, carriage rollers, lift and tilt cylinder operation, hydraulic oil pump, differential and transmission oil, fuel filter, positive crankcase ventilation valve and hoses

For diesel powered trucks

- Drain the water separator

Drain the water separator on diesel forklifts every 3 months

Maintenance to be Done Every 6 Months

Every six months or 1200 hours you should have the following maintenance done:

- Torque the engine head bolts and manifold nuts

- Inspect the brake booster operation

- Replace the brake fluid, wheel bearing grease coolant, fuel filter, fuel strainer element

For diesel powered trucks

- Replace the water separator

Contact Wayco to schedule preventative forklift maintenance today.

Replace the water separator on diesel trucks every 6 months

3. Annual Inspections

An annual forklift inspection is required by law to be carried out by a "competent" person who meets the requirements of the OHSA at least once a year. Clause 51(1)(b) of the OHSA states that after the initial inspection done before the first time you use your truck, your lift truck should be examined "as often as necessary but not less frequently than recommended by the manufacturer and in any case at least once a year." If you inspect your forklift after every 2,000 hours of use, you will generally meet this requirement. If your vehicle, though, you may have to do it more often. For example, if your lift truck is used to do double shifts over the course of the year, or if it is operated in severe environmental conditions such as extremely hot or corrosive environments, then the inspections should happen more often.

During the annual inspection, you should have the forklift's general safety and maintenance looked at to determine if it has be maintained in good condition and whether it is "constructed and equipped in a way to adequately ensure the safety of all workers." In addition to the general inspection, the lifting device's load-handling capacity should also be checked out to determine if it is capable of handling its maximum rated load.

To learn more about annual inspections and what they entail, check out our blog post entitled "2018 Guide to Forklift Inspection."

By law, forklifts need to be inspected annually

Choose Wayco for the Best Forklift Maintenance in the Tri-Cities

If you are looking for the best quality forklift maintenance at an affordable price, talk to the professionals at Wayco. At Wayco we have competent people on staff who are not only able to carry out your regular forklift maintenance, but we also have qualified individuals who are able to perform the annual lifting device inspection for you as required by the Ministry of Labour. During our full vehicle inspection, we will carefully examine all of the sections required to make sure that your devices are running properly and safely. Once your vehicles have been thoroughly inspected and found to be in proper working order, we can certify your equipment for you. You should keep this safety documentation organized and readily available for when a government inspector shows up. Contact Wayco today to schedule your lifting equipment inspection.

Contact Wayco if You Need Forklift Training

Wayco's intense and comprehensive forklift safety training program will provide you and your employees with the best safety training at the best price. We offer national coverage and local service with a 98% pass rate. We can train individuals or groups at our facility or yours - you choose.

Our Safe Operation of a Lift Truck/Forklift Program is an excellent way for you to ensure forklift safety in your workplace. With our training you will experience:

- Innovative training practices

- Affordable pricing

- Flexible and professional trainers

- Comprehensive in-class and practical experience

Contact Wayco today to book your next session.

"Our company shopped around for the most competitively priced lift equipment repairs and rental services in the KW region and found Waco Multi Lift Inc. Their repair rates were lower than the other companies out there and the service is prompt and professional for our in-house lift trucks. With one phone call, a tech arrives within a couple hours. We are also renting a 3-year-old lift truck from them in new condition, they found just the right truck for our needs. Their repair Techs are knowledgeable and friendly and get the job done no matter what the problem is. Just want to thank Steve P, Chris and Rob for their help the past few months for keeping our production and shipping rolling. " - CanadianBakeInn

Read more testimonials here.

If you are looking for top quality forklifts, contact Wayco. We sell the best forklifts you can buy and our knowledgeable staff will be able to help you choose the perfect model that will best suit your particular applications. We will be happy to answer all of your questions and we can even provide top-notch safety training for your operators. Contact Wayco today for all of your forklift needs.

Source: